Premium

An unparalleled technological evolution

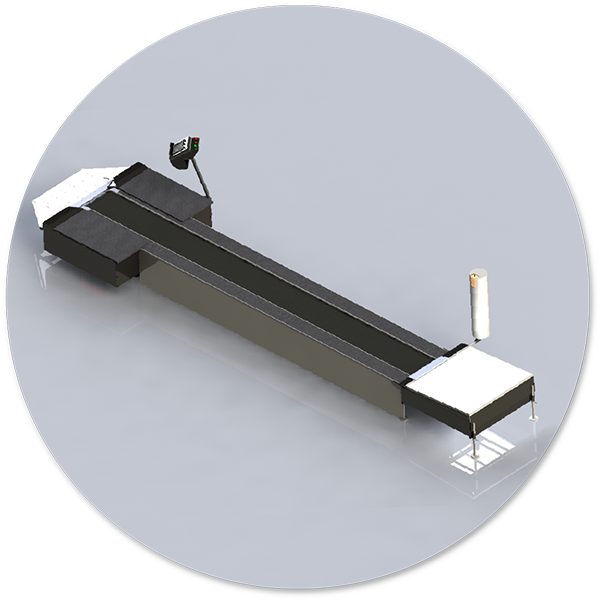

The Premium model represents the top-of-the-line of Team Service conveyor belts. Premium lift systems can reach lengths of over 400 meters and are available in three widths (650 mm, 810 mm, and 1200 mm). The model is distinguished by its extremely advanced and innovative technology. There are indeed multiple software functions available, controllable directly from the touchscreen located upstream of the system.

What applications is it most suitable for?

The Premium model has no usage limits. It is indeed the ideal solution for any type of need, from simple to more complex ones.

Technical Features

- Usable 365 days a year

- Three different widths available

- Made with high-quality materials

- Ground positioning through adjustable height feet

- Speed adjustable from 0.2 m/s to 0.7 m/s up to 1.2 m/s as an option

- Modular assembly system for quick installation and possible uninstallation in summer

- Pvc side protections, to keep the area under the carpet clean and level the snow to the level of the lateral walkway

- Side walkways in fiberglass coated with non-slip material

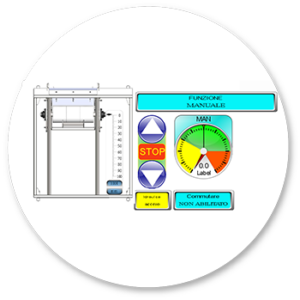

Command Column and Touchscreen

The control column is the fundamental and distinctive component of this model. It has a 12.1″ anti-glare, high-brightness touchscreen installed on it, which, when not in use, is protected from the weather by a lift-up cover.

From the touchscreen, you can manage the multiple functions of the system easily and immediately check for any malfunctions.

From the home page, you can choose or modify the language and speed of the system, display data such as the current day and time, outside temperature, rubber belt voltage, amperage, consumption, and engine temperature.

The software

The main functions and features

- The snow removal function allows for quick cleaning of the carpet after a snowfall. In this way, the snow is brought to the top and, by placing a snowplow near the exit, it can be removed quickly and effortlessly.

- The ice break function automatically eliminates ice between the rubber belt and the side walkways. By activating this function, the belt will move back and forth, in both directions.

- The anti-icing function can be activated at the end of the day when the conveyor belt is no longer in use. The belt will move automatically during the night, preventing the formation of ice.

- It is possible to view in real-time the status of the belt's safety systems and accurately locate the error that is blocking its operation. At every system stop, the type of malfunction and its location will be displayed on the touchscreen.

- The system displays and saves various information such as the number of people transported, hours of use, KW used, and motor amperage. This information is provided on a daily, weekly, monthly, and yearly basis. Using a USB key or connecting to the system with a PC, it is possible to download all of this data.

- The system can be connected to the internet. In this way, through remote assistance, 24/7 support can be provided in case of need. This service proves to be very useful in quickly resolving most of the operating problems that may arise. No additional costs are required, only a stable connection provided by the customer.

Additional Options

Customize your conveyor belt

In addition to the basic model, a series of additional elements can be selected by the customer, in order to create an even more performing and personalized product. They can be requested directly at the time of order, or they can be added as an integration at a later time. Here are some of the most relevant options to choose from.

Automatic pump

Once the desired pressure for the belt is set on the touchscreen, based on the load on the belt and the outside temperature, the pump automatically increases or decreases the pressure, always keeping it constant.

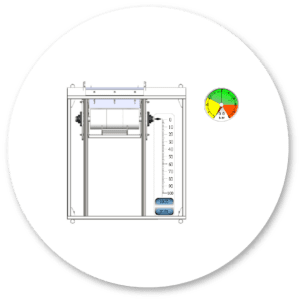

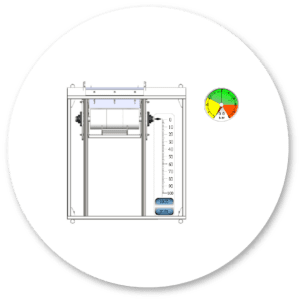

Tension carriage pressure

Thanks to the installation of a digital pressure switch, it is possible to monitor the tensioning pressure directly from the operating software homepage.

Tension carriage position

By installing a laser, it will be possible to control the exact position of the tension carriage.

Camera system

A camera system can be installed for the surveillance of the conveyor belt. This system proves to be extremely useful in order to control the belt without the help of an operator, thus saving the cost of personnel.

Rotating brush

A rotating brush can be installed under the drive roller and cleans the surface of the belt from any snow that accumulates. The brush is also important in case of summer use to clean the belt from dirt and mud. In this special configuration, in addition to the brush, a tube with nozzles that spray water on the surface of the belt is installed, making washing easier.

Secondary touchscreen

A secondary touchscreen allows controlling the carpet from another point of command, allowing to perform the same operations as the main touchscreen, without the need to dedicate an operator exclusively to its control.

The use of a secondary touchscreen is subject to the installation of a camera system.

Additional platform

It allows increasing the lateral walkways. It can be installed on the right, left, or on both sides of the conveyor belt, with a variable width.

Pacer

It serves to pace the ascent on the conveyor belt and is recommended on belts longer than 150m to respect the minimum distance between users.

SMS notification

In case of sudden shutdown of the system, it is possible to receive an SMS alert on one to twelve mobile phones, informing about the conveyor belt shutdown and the related error encountered.