Conveyor belt

Three models, infinite possibilities

A highly versatile solution, designed to meet a wide range of needs. Ideal for transporting people, canoes, rafts, bicycles, and more, it delivers exceptional performance even over lengths exceeding 1300 feet, ensuring flawless operation 365 days a year.

With adjustable speeds from 0,66 ft/s to 2,3 ft/s (optional up to 4 ft/s) and available in three widths (25,6″, 31,9″, and 47,5″), it perfectly adapts to a variety of applications.

To address specific market demands, three distinct models have been developed: Start, for those seeking an essential and functional solution, Easy, designed for greater versatility, and Premium, which represents the pinnacle of performance.

The distinctive features of our product

- High-quality galvanized steel frame, engineered to ensure maximum resistance to weather conditions and long-lasting durability, even in challenging environments.

- PVC side covers, a practical and effective solution to keep the area beneath the belt clean. This feature prevents the accumulation of dirt and snow, contributing to efficient and prolonged system operation. Additionally, the covers help level the snow, ensuring a uniform and safe surface along the lateral walkways.

- Height-adjustable ground supports, enabling quick and precise installation, perfectly adapting to different types of terrain. This solution simplifies system leveling, enhancing stability and operational efficiency.

- Stainless steel sliding tanks ensure exceptional resistance to corrosion and wear.

- Modular assembly system designed to optimize installation times, allowing for quick and easy setup.

- Fiberglass side walkways with anti-slip coating, combining durability, lightness, and safety. The anti-slip coating ensures excellent grip, even in wet or icy conditions, providing enhanced user safety.

- Rubber belt with customizable shortening during the first month of use. As a slight belt stretch is natural, customers can easily adjust it to the desired size at no additional cost. This offers significant advantages in terms of maintenance and operational flexibility, ensuring the belt remains in optimal condition.

- The belt is built according to EN15700 standards and complies with all current European safety regulations regarding operator maintenance procedures.

- Certified to international standards ANSI B77.1 and CSA Z98, and CE-marked, ensuring safety, quality, and reliability.

Main Applications

Ski Resorts

Ideal for transporting skiers quickly and efficiently

Ski Schools

A valuable aid for beginner skiers during lessons, facilitating easy ascent

Ski Domes

An essential component for uphill transportation in indoor artificial ski facilities

Ski Jumping Facilities

Extremely important for athlete training in ski jumping facilities

Mountain Bike Park

Perfect for the transportation of bicycles and integrable with belt cleaning systems

Amusement Parks

Widely used in summer at water parks

Tubing

Used for transporting tubing, sleds and other sports equipment

Parking areas

Perfect for transporting pedestrians and skiers between parking areas and ski facilities

Dry Slopes

An ideal support for uphill transportation in the presence of artificial ski slopes

Sport facilities

Indispensable in water spots for the ascent of canoes and/or rafts

The Start Model

Simplicity for everyone

Extremely simple and intuitive to use, the Start model is available exclusively in a width of 25,6″. This model has been specially designed for customers who need a quality conveyor belt, with a maximum length of 138 feet and at an affordable price.

What applications is it most suitable for?

- Perfect for ski schools that require a product that is simple and safe to use for beginners’ lifts.

- Suitable for small ski resorts looking for a conveyor belt of up to 138 feet in length at an affordable price.

Control Column

The Easy Model

A guarantee of versatility

The Easy model can be used in different contexts, from smaller to more complex systems. The customer has the option to choose from three available widths (25,6″, 31,9″, and 47,5″). The operator can adjust the speed of the system up to a maximum of 2,3 ft/s, optionally up to 4 ft/s.

What applications is it most suitable for?

The Easy model is suitable for all types of applications, with a maximum length of up to 492 feet.

- High safety for users and operators

- Adjustable speed at the operator’s discretion

- Usable 365 days a year, both in summer and winter

Control Column and Touchscreen

The control column is made from a weather-resistant plastic mold, housing the belt’s electronics for quick and easy access.

The control column features a 3.5ʺ touchscreen with a liftable cover, enabling easy management of system functions and immediate troubleshooting of malfunctions or stoppages.

Software: Key Features and Functions

- From the touchscreen, it is possible to turn on and off the infrared resistance. It is also possible to control the resistance through a timer, choosing a preset operating period for its activation and its relative shutdown.

- It is possible to view the report of the number of people transported daily and those transported since the start of the system's operation.

- By selecting the corresponding icon, it is possible to view the working hours of the conveyor belt.

- It is possible to view in real-time the status of the safety systems of the conveyor belt and accurately identify the error that blocks its operation. At each system stop, the type of error will be displayed on the touchscreen. It is also possible to view the inputs of the safety PLC.

The Premium Model

An unparalleled technological evolution

The Premium model represents the top-of-the-line of Team Service conveyor belts. Premium lift systems can reach lengths of over 1.312 feet and are available in three widths (25,6″, 31,9″, and 47,5″). The model is distinguished by its extremely advanced and innovative technology. There are indeed multiple software functions available, controllable directly from the touchscreen located upstream of the system.

The Premium Model Industry 4.0 certified (only available in Italy), with the possibility of recovering 20% of the investment over three annual installments, directly offsetting credits from taxes, contributions, and VAT payments.

What applications is it most suitable for?

The Premium model has no usage limits. It is indeed the ideal solution for any type of need, from simple to more complex ones.

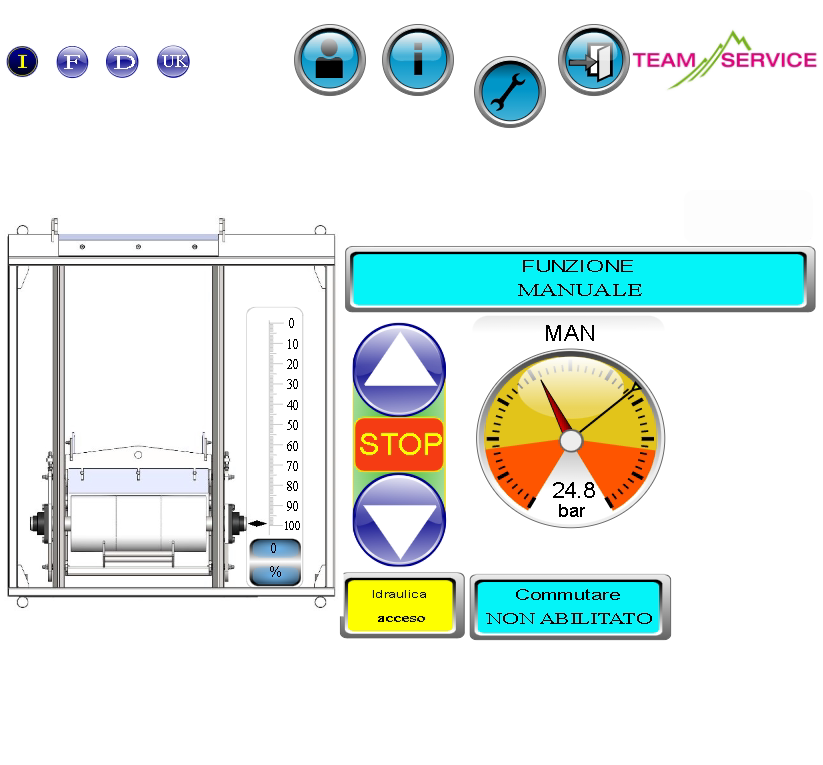

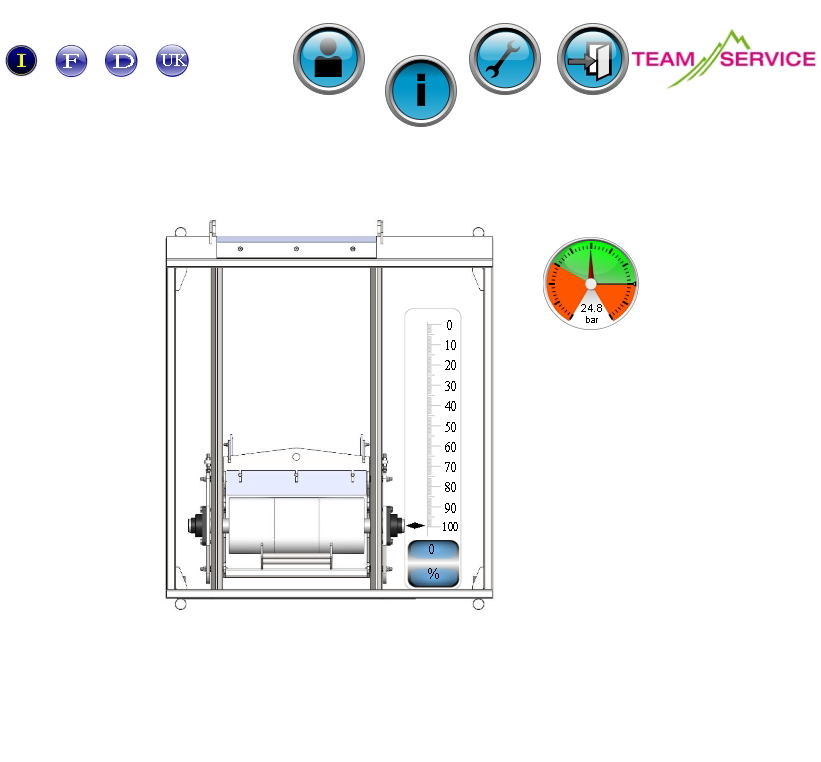

Control Column and Touchscreen

The control column is the fundamental and distinctive component of this model. It has a 12.1″ anti-glare, high-brightness touchscreen installed on it, which, when not in use, is protected from the weather by a lift-up cover.

From the touchscreen, you can manage the multiple functions of the system easily and immediately check for any malfunctions.

From the home page, you can choose or modify the language and speed of the system, display data such as the current day and time, outside temperature, rubber belt voltage, amperage, consumption, and engine temperature.

Software: Key Features and Functions

- The snow removal function allows for quick cleaning of the carpet after a snowfall. In this way, the snow is brought to the top and, by placing a snowplow near the exit, it can be removed quickly and effortlessly.

- The ice break function automatically eliminates ice between the rubber belt and the side walkways. By activating this function, the belt will move back and forth, in both directions.

- The anti-icing function can be activated at the end of the day when the conveyor belt is no longer in use. The belt will move automatically during the night, preventing the formation of ice.

- It is possible to view in real-time the status of the belt's safety systems and accurately locate the error that is blocking its operation. At every system stop, the type of malfunction and its location will be displayed on the touchscreen.

- The system displays and saves various information such as the number of people transported, hours of use, KW used, and motor amperage. This information is provided on a daily, weekly, monthly, and yearly basis. Using a USB key or connecting to the system with a PC, it is possible to download all of this data.

- The system can be connected to the internet. In this way, through remote assistance, 24/7 support can be provided in case of need. This service proves to be very useful in quickly resolving most of the operating problems that may arise. No additional costs are required, only a stable connection provided by the customer.

Additional Options

Customize your conveyor belt

In addition to the basic model, a series of additional elements can be selected by the customer, in order to create an even more performing and personalized product. They can be requested directly at the time of order, or they can be added as an integration at a later time. Here are some of the most relevant options to choose from.

Automatic restart

This system allows the conveyor belt to automatically restart after a temporary stop.

Automatic Start

The automatic start system allows for working in 'Energy Save' mode. It will be possible to stop or reduce the speed of the conveyor belt and then resume operation at the pre-set operating speed as soon as a customer reaches the boarding area.

Automatic

Pump

Once the pressure at which the belt should be tensioned is set, depending on the load on the belt and the outside temperature, the pump automatically increases or decreases the pressure, always keeping it constant.

Tension carriage pressure

Thanks to the installation of a digital pressure switch, it is possible to monitor the tensioning pressure directly from the operating software homepage.

Tension carriage position

By installing a laser, it will be possible to control the exact position of the tension carriage.

Camera system

A camera system can be installed for the surveillance of the conveyor belt. This system proves to be extremely useful in order to control the belt without the help of an operator, thus saving the cost of personnel.

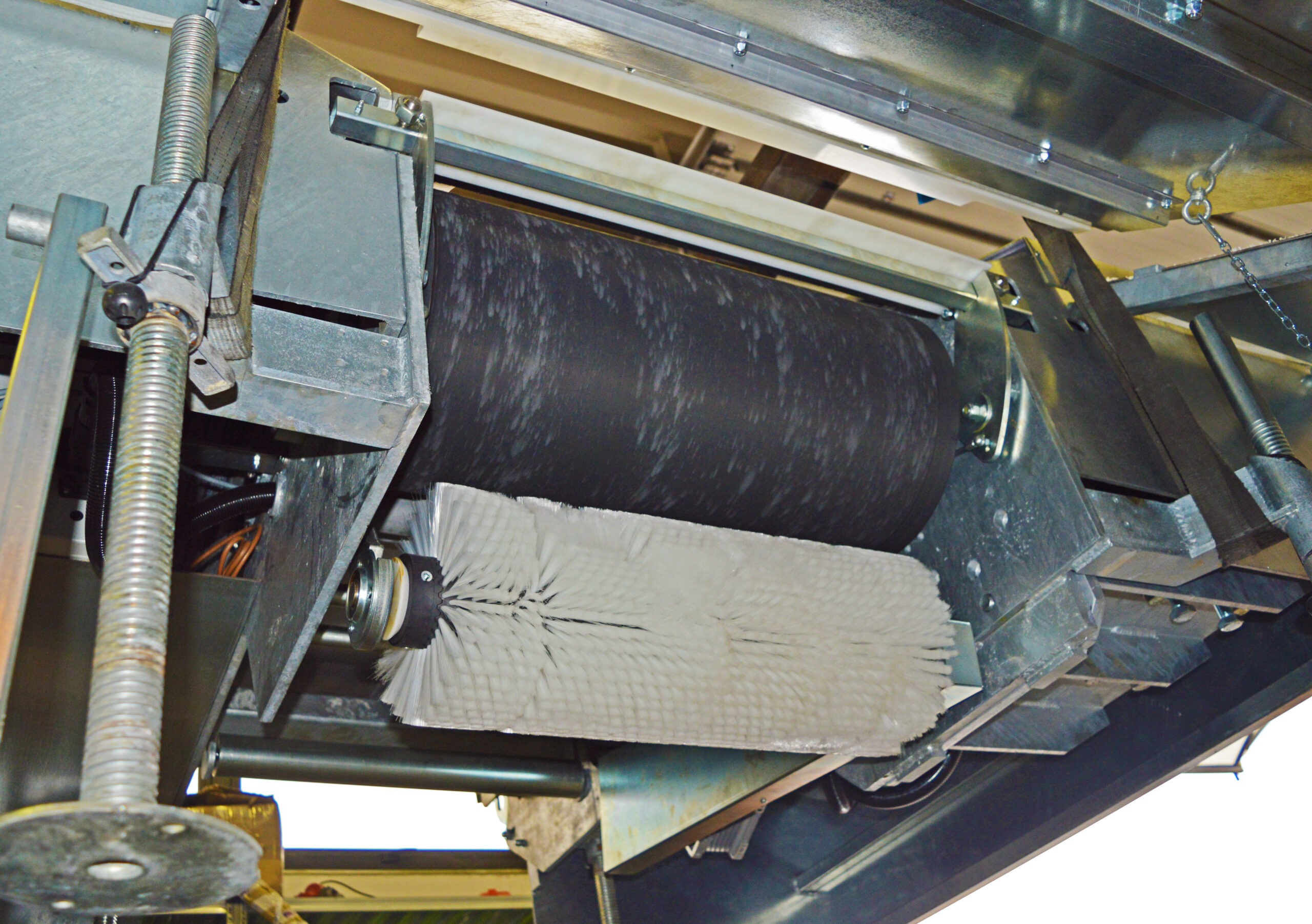

Rotating

Brush

It can be installed beneath the drive roller and cleans snow from the belt surface. The brush is also important in case of summer use to clean the belt from dirt and mud. In this special configuration, in addition to the brush, a tube with nozzles that spray water on the surface of the belt is installed, making washing easier.

Secondary touchscreen

It allows the conveyor to be controlled from another command point, enabling the same operations as the main touchscreen without the need to dedicate an operator exclusively to its control. The use of a secondary touchscreen is subject to the installation of a camera system.

Additional platform

It allows increasing the lateral walkways. It can be installed on the right, left, or on both sides of the conveyor belt, with a variable width.

Belt

Cadencer

It serves to pace the ascent on the conveyor belt and is recommended on belts longer than 492ft to respect the minimum distance between users.

Rubber belts

The two available models

Top Grip

The Top Grip belt ensures optimal grip in various operating conditions. The lower layer has a special resin finish that makes it waterproof, while the upper layer ensures optimal grip with skis, shoes or boots. The cylindrical surface allows skis to always have a direct support surface on the rubber, even when there is snow on its surface.

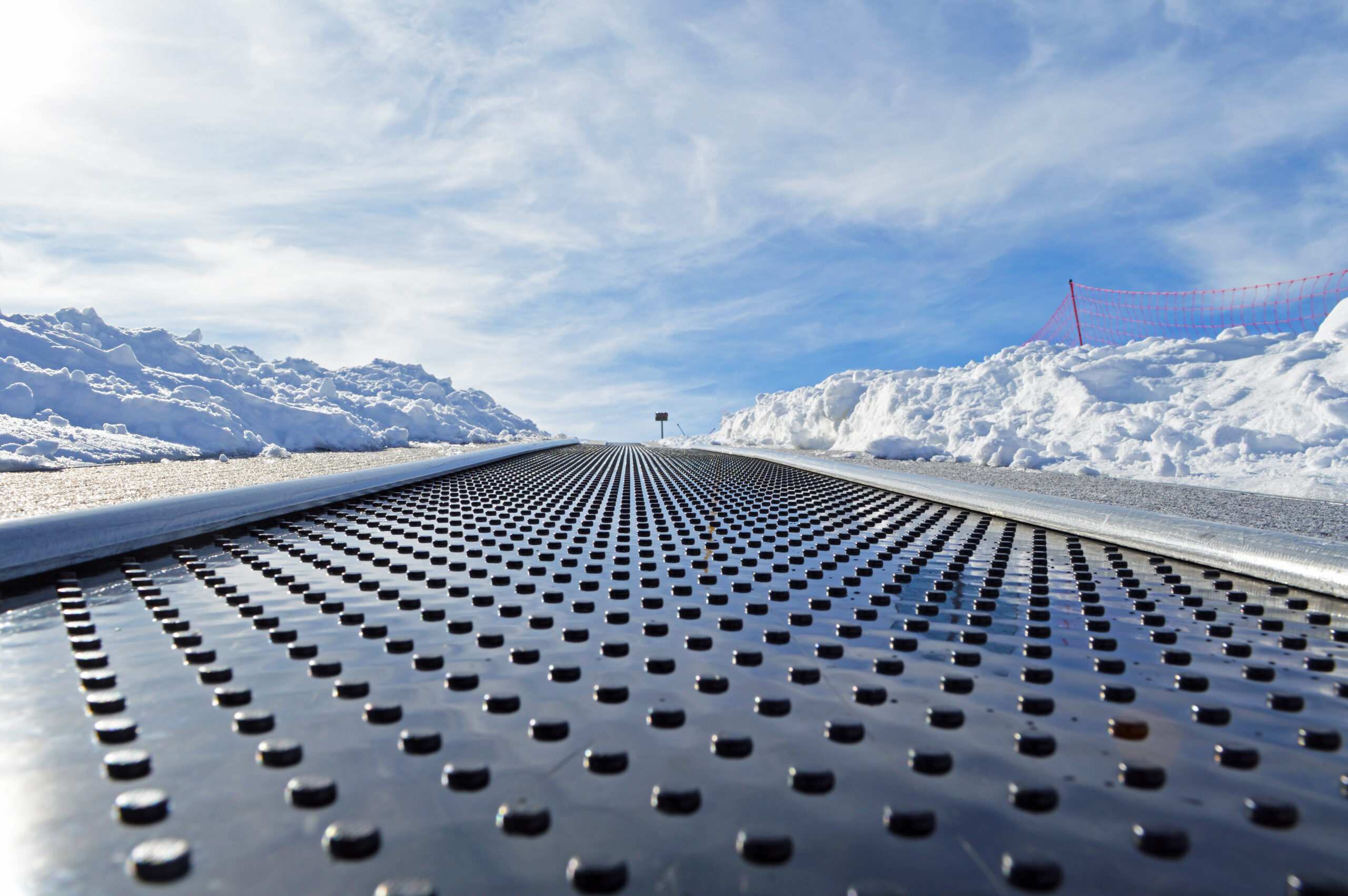

Bee Nest

The Bee Nest belt is characterized by its distinctive honeycomb surface. It has good resistance to abrasion, tearing, and high resistance to atmospheric agents. The composition of the weave guarantees an extremely low longitudinal elongation.